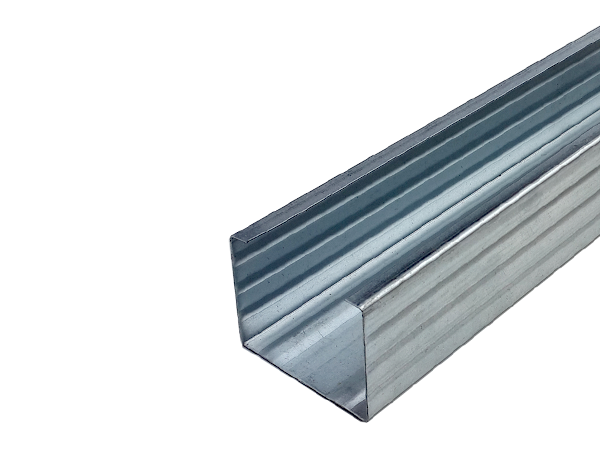

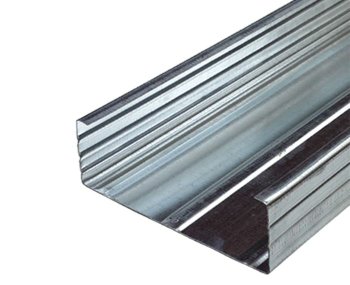

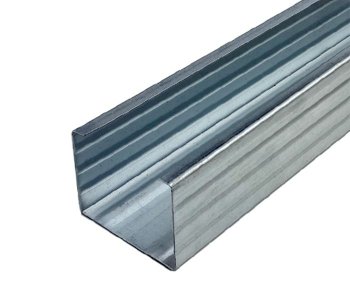

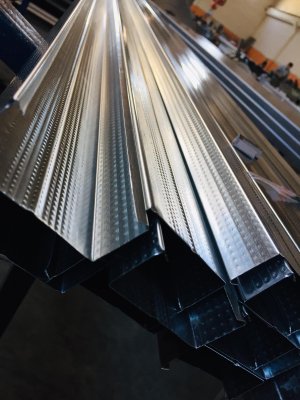

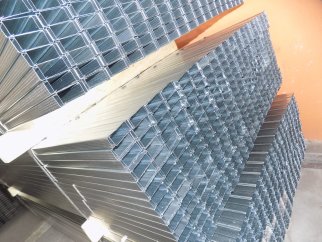

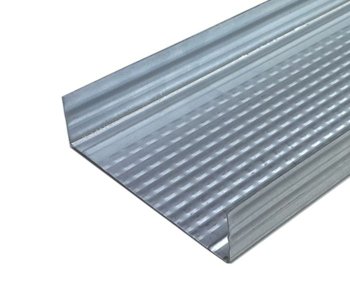

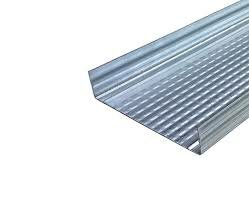

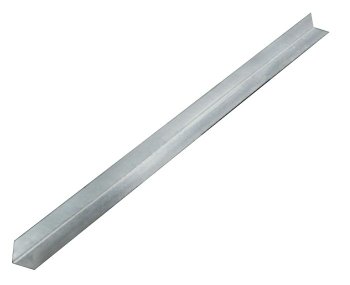

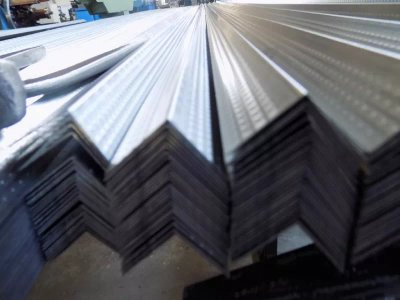

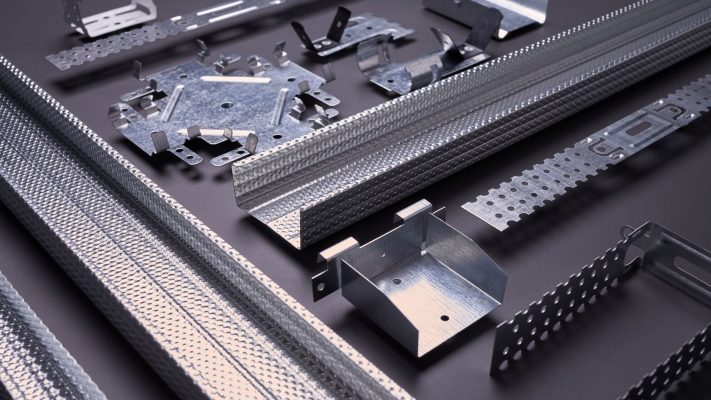

Drywall Profiles

Long-lasting Plasterboard Profile with advanced technology and flawless workmanship, which are compatible with your machines, produced from galvanized and corrosion resistant, are at Afra Profil at affordable prices!

Review 0552 528 70 38

Türkçe

Türkçe Français

Français العربية

العربية